Our expertise :

the pursuit of excellence

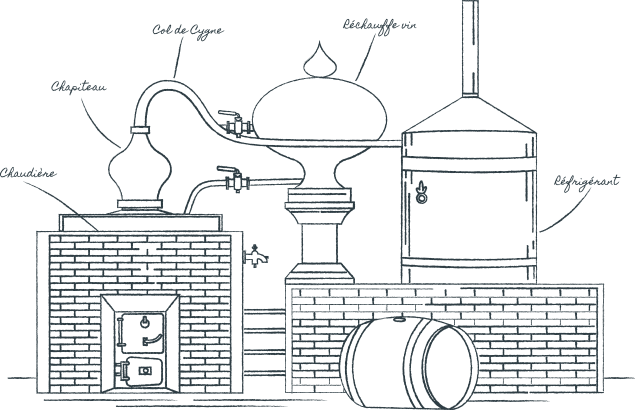

Our extensive knowledge of spirits, their traditional production methods, and a deep respect for the generational processes which have contributed to their great renown enables us to create exceptional distillations with a rich aromatic palette and well-defined intensity. Come into our cellars and discover this unique world that is a perpetual source of inspiration.